Recommended Grade:

| Grade | Binding phase(%) | Grain Size(um) | Density(g/cm3) | Hardness(HRA) | TRS(Mpa) |

| LBM10 | 6.0 | 1.2 | 14.7 | 89 | 2400 |

| LBM20 | 15.0 | 1.2 | 13.9 | 86.5 | 3000 |

| LBM30 | 20.0 | 1.0 | 13.5 | 86.2 | 3100 |

| LBM40 | 15.0 | 0.8 | 13.95 | 89.5 | 3600 |

| LBM50 | 7.6 | 1.2 | 14.10 | 90.2 | 3000 |

| BH05 | 6.0 | 2.4 | 14.80 | 90.0 | 3000 |

| BH12 | 13.0 | 1.4 | 14.15 | 89.0 | 3500 |

| BH15 | 15.0 | 1.2 | 13.85 | 88.2 | 3800 |

Size and Tolerance:

| L(mm) | W(mm) | H(mm) |

| 100 | 100 | 1.5~70 |

| 105 | 105 | 1.5~70 |

| 110 | 110 | 1.5~70 |

| 120 | 120 | 1.5~70 |

| 150 | 150 | 1.5~70 |

| 200 | 200 | 1.5~70 |

| 250 | 250 | 1.5~70 |

| 300 | 300 | 1.5~70 |

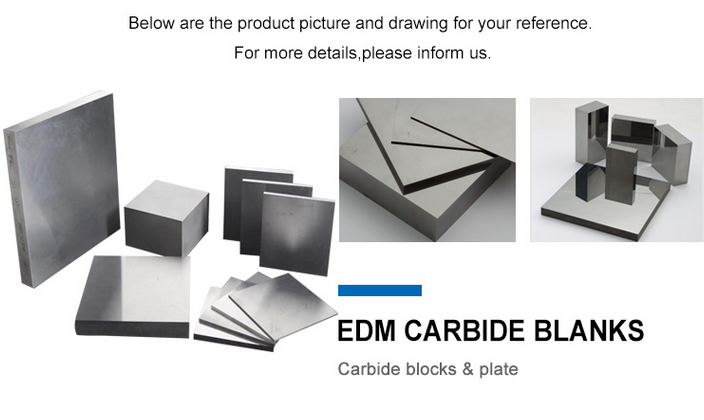

Tungsten Carbide Plates Features

1. 100% virgin tungsten carbide materials.

2. Sintering and ground surface.

3. Composition: WC+Co, WC+TiC+TaC+Co.

4. ISO9001:2008 vertified professional manufacturer over 10 years.

5. OEM and ODM are accepted as well.

Tungsten Carbide Plates Application

1.Used for heat-resistant parts, wear-resistance parts, anti-shielding parts, anti-corrosion parts.

2.Used for making progressive press tools and progressive dies of high velocity ram machine.

3.Used for making connectors in electron industry, IC industry and semiconductor

4.Used for armature, stator, LED lead frame, EI silicon steel sheet and punching mould for hardware and standard parts.

Related Products

We are a professional tungsten carbide manufacturer,We already have over 10 years of experience in research and manufacturing of tungsten carbide products.

We are Professional manufacture of Carbide stone cutting inserts,sand making machine alloy strip,wear parts,carbide mining tools and OEM production as drawing and request.