In various industry tungsten carbide mechanical seal rings are often applied due to their outstanding properties. In this article, Langsun Carbide will provide a comprehensive overview of tungsten carbide mechanical seal rings, including their properties, manufacturing methods, and applications. We will also discuss some common issues and solutions in the applications of tungsten seal rings.

1.Tungsten Carbide Mechanical Seal Rings Market Coordination Trend Analysis

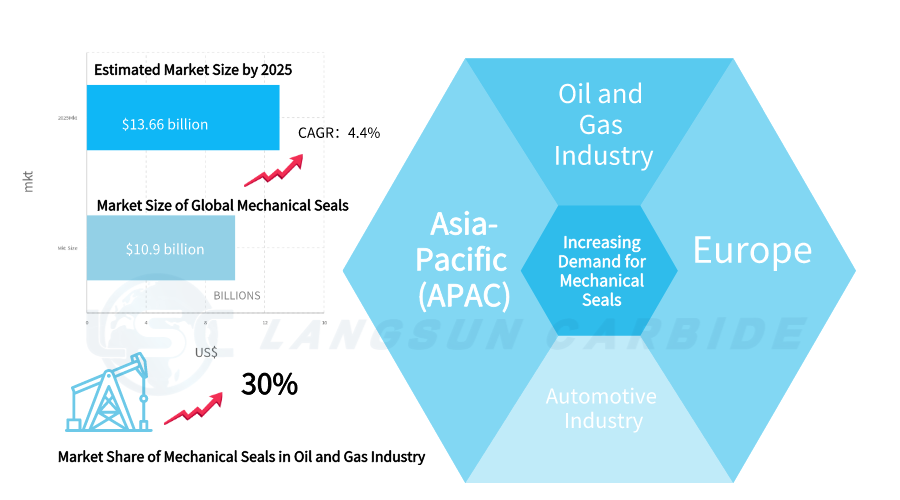

This table shows the market size of the global mechanical seals industry and its estimated market size by 2025, along with the compound annual growth rate (CAGR)

2.Properties of Tungsten Carbide Mechanical Seal Rings

Tungsten carbide mechanical seal rings are well known for their high hardness, wear resistance, and chemical stability. They possess a low coefficient of friction, which will help to lower heat generation and energy consumption. Tungsten carbide is resistant to corrosion and high temperatures, making it ideal for use in demanding environments.

3.Manufacturing Methods of Tungsten Carbide Mechanical Seal Rings

Various methods produce tungsten carbide mechanical seal rings, including powder metallurgy, hot pressing, and hot isostatic pressing. The powder metallurgy method entails blending tungsten carbide powder with a binder and pressing the mixture into the desired shape. Hot pressing involves heating the powder mixture to a high temperature and applying pressure to shape the seal ring. Hot isostatic pressing uses high temperature and pressure to produce a dense and uniform structure.

4.Applications of Tungsten Carbide Mechanical Seal Rings

Tungsten carbide mechanical seal rings are used in lots of across multiple industries, such as oil and gas, chemical processing, and water treatment. They serve to seal fluids in pumps, compressors, and other equipment. Additionally, the aerospace industry uses tungsten carbide seal rings to seal hydraulic systems and fuel pumps.

5.Common Issues and Solutions in the Use of Tungsten Carbide Mechanical Seal Rings

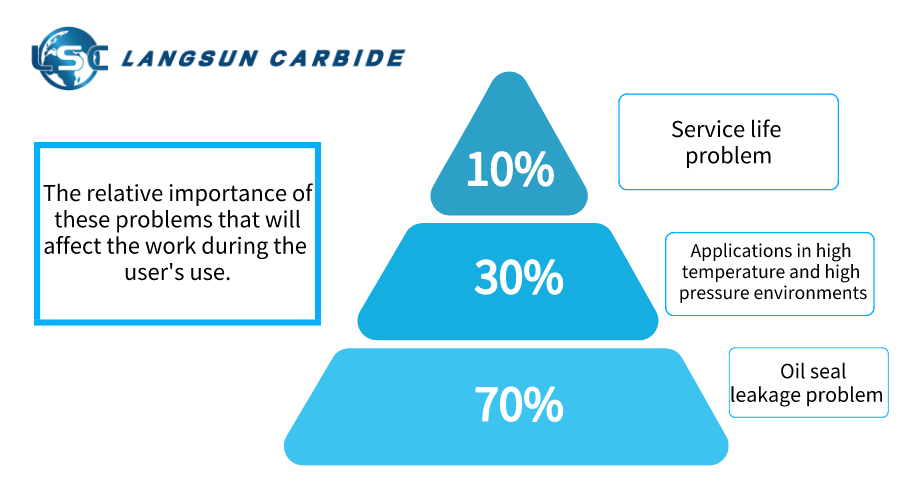

Despite their excellent properties, tungsten carbide mechanical seal rings can still experience issues in their use. Some common problems include wear, leakage, and damage from vibration. Proper maintenance and installation can help to mitigate these issues. For example, ensuring that the seal ring is installed correctly and the mating surfaces are properly aligned can help to prevent leakage. Regular inspections and cleaning can also help to identify and address any issues before they become more serious.

We also made a table to express how much the efficiency of the mechanical seal ring will be affected by the problems encountered by the user during use.

6.Conclusion

Tungsten carbide mechanical seal rings are an important component in various industrial applications. They offer excellent properties, including high hardness, wear resistance, and chemical stability. With proper manufacturing, installation, and maintenance, tungsten carbide mechanical seal rings can provide reliable and long-lasting performance.

Industry and Academic Sources

Sources consulted for this article include "Mechanical Seals: Theory and Applications" by J. M. Porteous and "Handbook of Mechanical Engineering Calculations" by Tyler G. Hicks. Additionally, industry-specific sources were consulted, including "Pump Handbook" by Igor Karassik and "Chemical Process Equipment, Selection and Design" by Stanley M. Walas.