Tungsten-carbon binary system can form two kinds of crystalline carbides, namely WC and W2C. Among them, WC is the main raw material for manufacturing cemented carbide, and also the important raw material powder for preparing high wear resistant coatings in the field of thermal spraying. WC has high hardness, especially at high temperature. WC can be well wetted by metal melts such as Co, Ni and Fe, especially by cobalt melt. When the temperature rises above the melting point, WC can dissolve in these metal melts, and when the temperature decreases, WC can precipitate. These excellent properties make it possible to use cobalt or nickel as bonding phase materials, after high temperature sintering or coating treatment, to form a wear-resistant coating with good wear resistance.

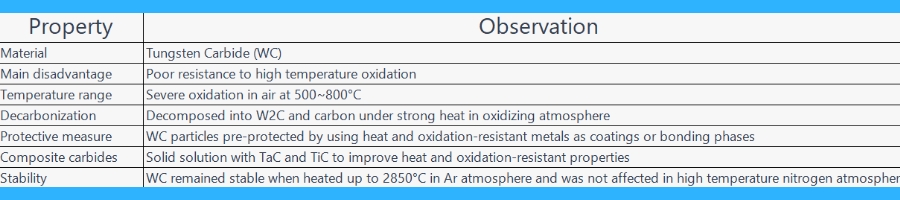

The main disadvantage of WC is its poor resistance to high temperature oxidation. It suffers from severe oxidation in air of 500 ~800 C. It is easy to be decomposed into W2C and carbon under strong heat in oxidizing atmosphere, which is called "decarbonization". WC particles can be pre-protected by using heat-resistant and oxidation-resistant metals as coatings or bonding phases, and composite carbides can be formed by solid solution with TaC and TIC to improve the heat-resistant and oxidation-resistant properties of WC. WC remained stable when heated to 2850 degrees Celsius in Ar atmosphere and was not affected in high temperature nitrogen atmosphere.

The melting point and hardness of W2C are higher than that of WC. It can form W2C+WC eutectic mixture with WC. The melting point decreases and it is easy to cast. It is called "cast tungsten carbide" or "fusible tungsten carbide". The content of carbon is 3.8%~20%(mass), of which W2C is 78%~80%(mass) and WC is 20%~22%(mass). This cast tungsten carbide is the hardest and most wear-resistant material with low cost.

WC powder can also be mixed with cobalt-based, nickel-based and iron-based self-fluxing alloy powders, nickel-aluminum self-bonding composite powders. It is widely used in the preparation of high wear-resistant coatings, especially in the areas of abrasive wear, hard surface wear and mud-sand erosion wear. Tungsten carbide powder is mainly used as raw material powder for thermal spraying wear-resistant coating.

Vacuum plasma spraying and protective atmosphere tungsten carbide plasma spraying can be used for wear-resistant coating, but the adhesion of the coating is not good.

Langsun Carbide has all kinds of shapes and sizes of cemented carbide products including carbide rods, carbide plates, carbide rings, carbide bushings, carbide nozzles, carbide balls, valves and nonstandard carbide parts. We feel very pride that our tungsten carbide products are widely used in the following fields, Mechanical seals, oil and natural gas industry, New Energy, Military industry, Aerospace, Auto parts industry, Steel smelting, Coal mining, Chemical industry. More detail: www.ls-carbide.com