The oil industry relies heavily on sophisticated equipment to ensure the efficiency and effectiveness of drilling operations. Among these crucial components are tungsten carbide PDC drill bit nozzles. These nozzles play a pivotal role in the extraction process, enhancing the performance and longevity of drilling tools.

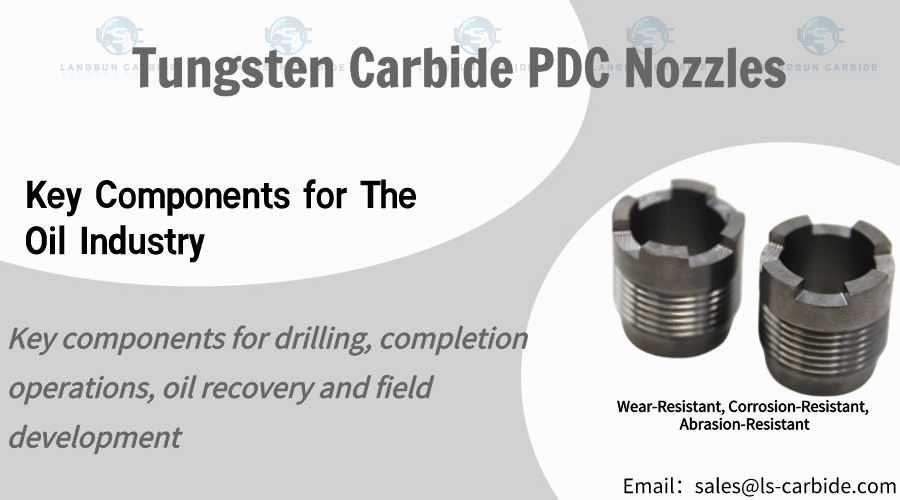

Tungsten carbide is known for its superior hardness and wear resistance, making it an ideal material for PDC nozzles. These nozzles are made from superior tungsten carbide raw material, which further enhances their durability and wear resistance. This enables PDC bit nozzles to withstand the extreme pressures and abrasive conditions encountered in drilling operations.

Tungsten carbide PDC nozzles are renowned for their exceptional hardness and durability. Tungsten carbide itself is among the hardest materials available, the resultant nozzle exhibits remarkable resilience against wear and tear. The high hardness of these nozzles ensures that they can withstand the extreme conditions encountered during drilling, including high-impact forces and abrasive environments.

The unique properties of tungsten carbide drill bit nozzles significantly improve drilling efficiency. These nozzles facilitate the directed flow of drilling fluids, which helps in cooling the drill bit and clearing debris from the drill path. The efficient fluid flow reduces downtime and promotes faster drilling speeds, enhancing overall productivity.

The design of tungsten carbide PDC nozzles allows for precise and controlled fluid delivery. This attribute is essential for optimizing the drilling process, ensuring the effective removal of cuttings and minimizing the risk of blockages. The enhanced fluid dynamics provided by these nozzles contribute to smoother operations and better borehole quality.

Drilling operations are often subjected to harsh environments and extreme pressures. Tungsten carbide PDC nozzles are engineered to withstand these conditions, maintaining their structural integrity and performance. Their resistance to high temperatures and abrasive substances ensures consistent functionality throughout the drilling process.

PDC drill nozzles perform two important functions in drilling operations:

Cooling the drill bit: Under high temperature and high pressure, the high-speed rotation of the drill bit generates a large amount of heat. The tungsten carbide nozzle can effectively cool the drill bit by spraying mud liquid at high pressure to avoid damage due to overheating.

Cleaning the drill bit: The nozzle can continuously spray mud liquid to take the rock chips generated during drilling out of the hole, thus keeping the drill bit clean and ensuring the drilling efficiency.

Tungsten carbide PDC nozzles are utilized in various aspects of drilling operations. Their applications range from standard oil drilling to more specialized activities, such as horizontal drilling and offshore exploration. Here are a few specific applications:

Tungsten carbide PDC nozzles are commonly integrated into standard drill bits, enhancing their performance and reliability. By optimizing fluid dynamics, these nozzles contribute to effective cutting action and debris removal, essential for efficient drilling.

In horizontal drilling, maintaining fluid flow and ensuring the removal of cuttings is challenging. Tungsten carbide PDC nozzles play a crucial role in overcoming these challenges, facilitating the directed flow of drilling fluids and improving the efficiency of horizontal wells.

Offshore drilling involves extreme conditions, where equipment must withstand high pressures and saltwater corrosion. The robust nature of tungsten carbide PDC nozzles makes them ideal for offshore applications, ensuring reliable performance and longevity.

The following factors need to be considered when choosing the right nozzle for a tungsten carbide PDC drill bit:

Nozzle orifice size: Different formations and drill types require different sized orifices to ensure jetting flow and cleanliness.

Nozzle material: Although tungsten carbide is commonly used, other materials may need to be compounded for specific environments to increase corrosion resistance or enhance durability.

Design and construction: The design of the nozzle needs to be matched to the overall construction of the drill to ensure its stability and efficiency under high pressure conditions.

Tungsten carbide nozzles are essential mechanical components in the oil industry, contributing significantly to drilling efficiency, durability, and overall performance. Their unique properties and practical applications make them indispensable in extracting oil efficiently and safely. By understanding the critical role these nozzles play, industry professionals can appreciate their value and continue to leverage their benefits in various drilling operations.

Implementing PDC drill bit nozzles in drilling equipment is a testament to the industry's commitment to advancing technology and optimizing processes. As the oil industry evolves, these nozzles will undoubtedly remain a cornerstone of effective and efficient drilling.