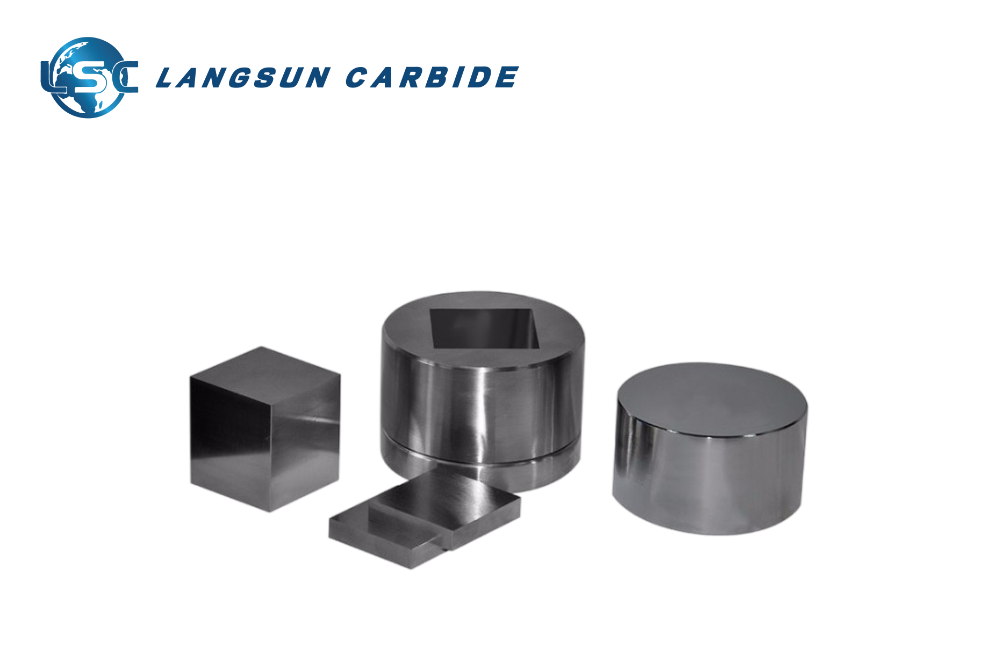

Tungsten carbide dies transform raw metals into precision components across aerospace, automotive, and energy industries. Langsun Carbide's carbide dies meet the highest standards for durability and performance, are ISO 9001 certified, and have a service life 10-15 times longer than tool steel molds, with dimensional tolerances as low as **±0.003 mm**, meeting the needs of a wide range of industrial applications.

Tungsten carbide (WC-Co) combines:

Ultra-Hard WC Grains: 1,500–2,200 HV hardness

Ductile Cobalt Matrix: 6–15% binder for shock absorption

| Property | Tool Steel | Tungsten Carbide | Improvement |

|---|---|---|---|

| Hardness (HRA) | 60–70 | 89–93 | 30–50% ↑ |

| Wear Resistance | 1X (Baseline) | 10–15X | 900–1,400% ↑ |

| Surface Finish (Ra) | 0.4–0.8 μm | 0.1–0.3 μm | 60–75% ↑ |

| Compressive Strength | 2,500 MPa | 4,500–6,000 MPa | 80–140% ↑ |

Source: ASM Handbook Vol. 16 (2023 Edition)

Langsun Carbide can customize and manufacture various types of tungsten carbide dies according to customer requirements and drawings, including but not limited to: Wire Drawing Dies, Cold Heading Dies, Extrusion Dies, and Forging Dies.

Tungsten carbide dies are versatile tools used in various industries, including:

Automotive Manufacturing: For producing precision components such as fasteners and connectors.

Aerospace Industry: In the fabrication of high-strength, lightweight parts.

Metalworking: For shaping and forming metals in industrial processes.

Electronics: Used in the production of electronic components and connectors.

Langsun Carbide is dedicated to providing high-quality, reliable tungsten carbide solutions. Our expertise in carbide technology ensures that our products deliver exceptional performance and durability. We pride ourselves on our ability to produce customized solutions that exceed industry standards and customer expectations.