Tungsten carbide remains the gold standard for industrial wear components – from drill bit inserts to extrusion dies – due to its unparalleled hardness (1,500-2,000 HV) and fracture toughness.making it an ideal material for wear parts across various industries. However, even tungsten carbide components can benefit from enhancements to their wear resistance to extend their service life and performance.

In critical applications, even a 10% improvement in wear resistance yields dramatic operational benefits:

| Industry Application | Failure Consequence | Target Improvement |

|---|---|---|

| Oil & Gas Drill Bits | Well abandonment ($5M+) | 30% longer service life |

| Steel Roller Mills | Production line shutdown | 0.05mm/month wear rate |

| Valve Seals (HPHT) | Hazardous fluid leaks | Zero erosion at 25,000 psi |

Source: ASM Handbook Vol. 18 (2020)

Cemented carbide has excellent comprehensive properties such as high strength, high hardness, high elastic modulus, high toughness and high wear resistance. Widely used in mine and oil extraction tools, industries that require high wear resistance, such as molds and wear-resistant parts. The wear performance of cemented carbide wear parts is affected by factors such as the use environment and the performance of the tungsten carbide wear parts.

The wear resistance of carbide parts is mainly determined by the microstructure and chemical composition of the tungsten carbide wear parts. The main structural parameters of cemented carbide are: grain size and binder phase content. The wear resistance of carbide parts is also affected by additive elements such as boron.

| Binder Type | Cobalt Content | Advantages | Trade-offs |

|---|---|---|---|

| Conventional Co | 6-12% | Optimal toughness | Vulnerable to acid corrosion |

| Ni-Cr-Mo Alloy | 8-10% | 5x corrosion resistance | 10% lower fracture toughness |

| Fe/Ni Gradient | 6%→15% | Custom zone properties | Requires HIP |

In the development of modern technology and industrial production, many important mechanical equipment and its mechanical parts are under harsh working conditions, such as high speed, high temperature, high pressure, heavy load, etc. Damage by corrosion, oxidation, etc. occurs frequently. Steel damage caused by friction and wear mostly starts at the surface. The use of surface protection measures to delay and control the damage of the surface has become an effective method to solve the wear problem of tungsten carbide wear parts.

| Treatment | Thickness (μm) | Hardness (HV) | Best Application |

|---|---|---|---|

| CVD Diamond Coating | 10-30 | 9,000-10,000 | Abrasive slurry components |

| HVOF WC-10Co-4Cr | 100-300 | 1,200-1,400 | Large-scale erosion protection |

| Laser Cladding | 500-2,000 | 1,400-1,600 | Repair/rebuild of worn parts |

| Plasma Nitriding | 50-150 | 1,800-2,200 | Fatigue-sensitive |

Various anti-wear technologies on the surface of mechanical parts, such as coating, thermal infiltration, carburizing, nitriding, metal infiltration, thermal spraying, surfacing, coating (physical and chemical vapor deposition, separation (sub-plating), paste hardening layer, high-energy beam (laser or electron beam cladding, ion implantation), etc. Diluted metal has been successfully used in tungsten carbide wear-resistant parts. While improving carbide strength and impact toughness by more than 10%, the wear resistance of tungsten carbide wear parts wear-resistant parts has also been improved.

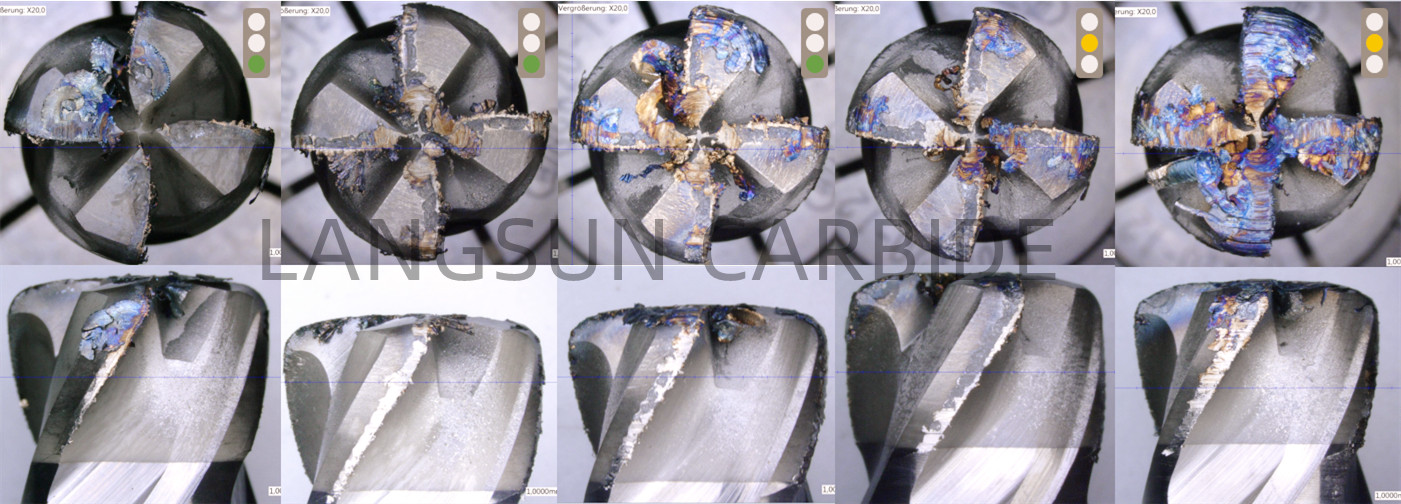

Surface protection of tungsten carbide parts to control surface damage is the most effective way to solve the wear problem of TC wear parts. LANGSUN CARBIDE has a variety of surface strengthening technologies, such as plasma surfacing welding, supersonic spraying, gas shielded welding, vacuum cladding, etc., can better protect tungsten carbide wear-resistant parts and prolong the service life.

Enhancing the wear resistance of tungsten carbide parts requires a combination of technologies such as material optimization, manufacturing processes and surface treatments. By implementing these strategies, industries can maximize the life and performance of tungsten carbide parts. Langsun Carbide is committed to providing high-quality, wear-resistant tungsten carbide parts to meet the specific needs of our customers. Our expertise and dedication to innovation ensures that our products provide superior durability and reliability even in the most demanding applications.