Tungsten carbide, also known as hard metal, is widely used in various industries due to its exceptional hardness, wear resistance, and toughness. From cutting tools to carbide nozzle or tungsten bushings, tungsten carbide plays a critical role in many applications. Metallographic microanalysis, a powerful technique used in materials science, provides valuable insights into the composition, structure, and properties of cemented carbides, helping engineers and researchers unlock the secrets of these remarkable materials.

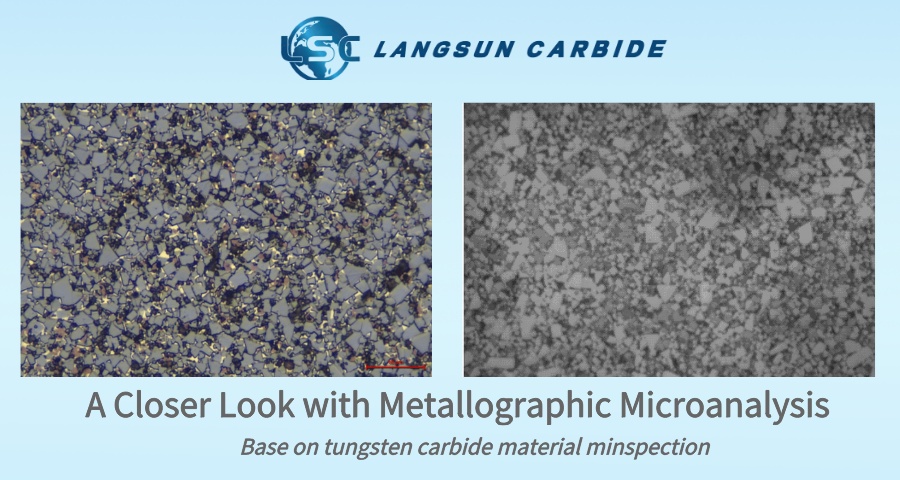

Metallography is the study of the microscopic structure of materials using optical microscopy, electron microscopy, and other specialized techniques. Cemented carbides are composite materials composed of hard carbide particles, typically tungsten carbide (WC), embedded in a metallic binder, usually cobalt (Co) or nickel (Ni). Metallographic microanalysis enables detailed examination of the carbide particles, binder phase, and their interfaces, shedding light on their morphology, distribution, and chemical composition.

一、The content of metallographic analysis of tungsten carbide

1. Defects

1. Pores

2. Graphite

3. Macro holes

4. Others (unpressed, cracked, delaminated)

二、Organizationon

1. Determination of grain size (distribution of grains)

2. Decarbonization

3. Cobalt layer thickness

Purpose of metallographic analysis

Tungsten carbide is made by powder metallurgy method, which is a solid phase transformation process. Therefore, there are various defects with process characteristics in the interior and surface of these alloy products, such as pores, graphite, dirt, η, etc. Qualitative and quantitative analysis of these defects is an important part of determining product quality. It is very important to identify the various structures inside these alloys, which can reveal whether each link of the process (including mixing, pressing, and sintering) is correct or not.

In order to ensure the quality of our products, LANGSUN CARBIDE will carry out strict material analysis for each batch of raw materials, so that all the hard alloy products we produce include sealing rings, carbide bushings, carbide nozzles and other products, so that Customers can use it with peace of mind.

The reference information for this article comes from<<Compilation of Metallographic Inspection Standards>>;

<<Standard metallographic examination spectrum>>;

Ningbo Langsun Tungsten carbide Co.,LTD lab.